VIECONN-M400

Categorie:

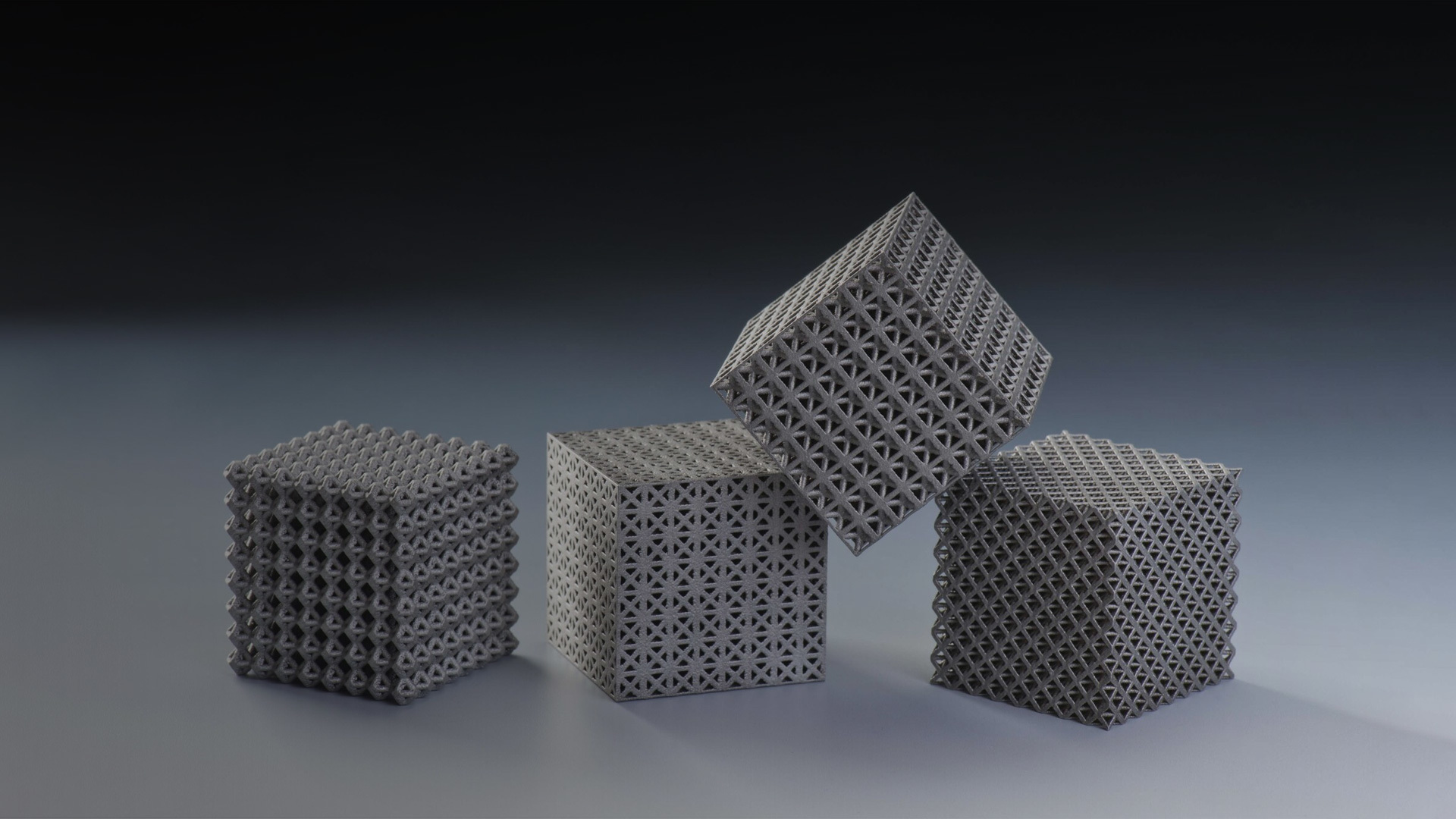

The machine uses laser melting technology to selectively scan the metal powder according to the layered cross-section information of the digital model, and finally melt the metal powder layer by layer.

Details

The machine uses laser melting technology to selectively scan the metal powder according to the layeredcross-section information of the digital model, and finally melt the metal powder layer by layer.

The equipment has the characteristics of high molding accuracy, good stability, interactive humanization and high safety.

It adopts high sealing molding chamber design, advanced optical path system, excellent wind field design, high-pre-cision servo motor and screw transmission mechanism to ensure stable molding accuracy and speed, stableoperation and simple operation.

Powder sealing operation, anti-static treatment, explosion-proof safety treatment and other safety design, to achieve real-time monitoring of equipment working status, abnormal automatic alarm, to ensure the safe and reliable operation of equipment.

Equipment Specifications

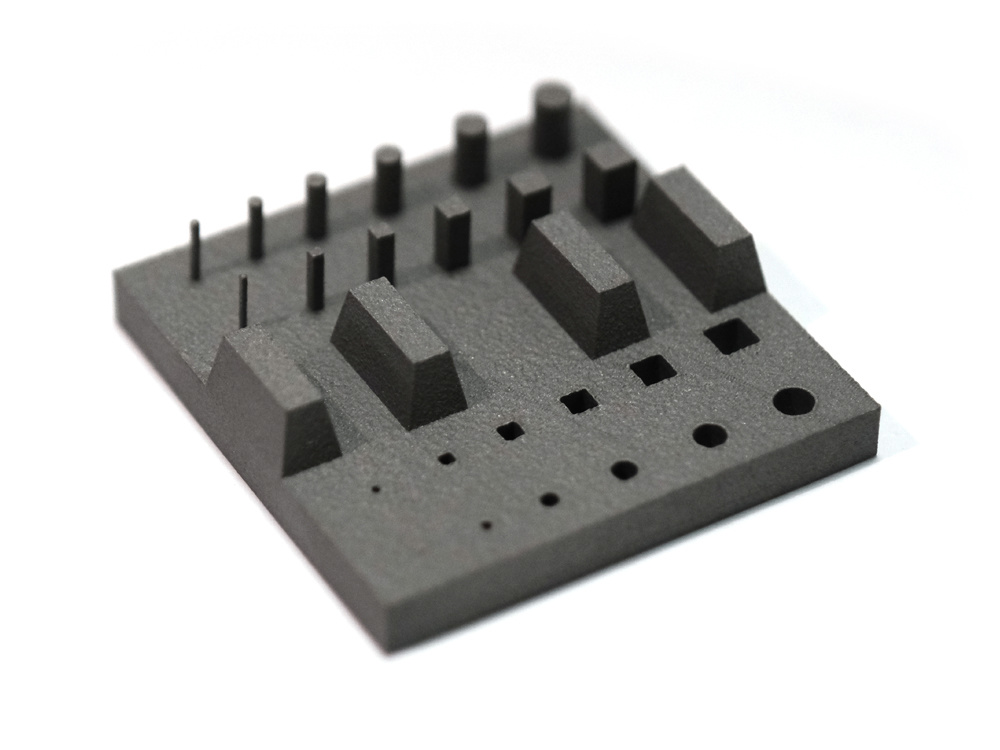

| Formed material | Stainless steel / titanium alloy / aluminum alloy / die steecobalt chromium alloy / nickel base alloy, etc |

| Main size of equipment (L×W×H) | 3790×1520×2460mm The feed tank heightis not included |

| Molding size (L×W×H) | 400×300×400mm |

| Lasertype | IPG fiberlaser · 500W×4 |

| Molding precision | 0.1mm / 100mm |

| Molding speed | 65-140cm3/h |

| Forming thickness | 0.02-0.1mm |

| Table repeated positioning accuracy | ±5μm |

| Inert gas consumption (during printing) | 1L/min |

| Power requirement | 380VAC/50HZ/15KW Three-phase five-wire |

| Auxiliary engine interface specifications | KF50 Host and material machine, feeder interface |

| Optical quality | M2≤1.1 |

| Maximum scanning speed | 7m/s |

| Preheating temperature | RT+20℃-200℃ |

| Particle size of powder | 15-53μm |

| Data format | STL |

| Installation (unit) weight | ≈3.5t |

| Environment temperature | 18-25℃ |

| Ambient humidity | ≤60% |

| Minimum oxygen content | ≤100ppm |

| Air source requirement | Ar |

Equipment Advantage

- 407×307 format, height 400, using four laser printing, rapid prototyping.

- Double powder trough with scraper to achieve accurate bidirectional powder laying, efficiencycan be increased by 40%.

- Material support: stainless steel, aluminum alloy 6013, titanium alloy, etc. can be customized for different materials according to customer needs.

- All imported optical system, imported IPG laser, galvanometer, field mirror, beam expanding mirror.

- Scraper holder Suitable for various scrapers (ceramic scraper, stainless steel scraper, rubber scraper, brush scraper).

- Equipped with raster ruler, Z-axis accuracy is higher.

- The heating plate is equipped with water cooling plate to accurately control the heating temperature.

- Double oxygen meter detects oxygen content to achieve double insurance, one damage to the other can also ensure oxygen content monitoring.

- The number of laser equipment can be customized by customer needs (single light \ double light \ three light \ four light).

- Can use Magics, Mange and other software slicing slicing format diversity, device adaptation, higher compatibility.

- Low oxygen content, good air tightness, less air consumption, 1L/min.

- Open source parameters, real-time adjustment of printing parameters to meet diverse production needs.

- Dc air field layout, full format printing effect is better, quality is more reliable.

- The scraper frame is optimized (bilateral fixation), the screw is used to match the top wire, and the scraper is more convenient and easier to use.

Keywords:

VIECONN-M400

3D Printing Service

3D Printing

3D Printing

3D Printing

3D Printing

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!